Author identifiers

Google Scholar: https://scholar.google.com/citations?user=cNEMmBkAAAAJ

Scoupus: https://www.scopus.com/authid/detail.uri?authorId=36774019000

ORCID: https://orcid.org/0000-0001-8481-0059

Research ID (Publons): https://publons.com/researcher/A-1531-2012/

ResearchGate: https://www.researchgate.net/profile/Xu_Zhang

Mendeley: https://www.mendeley.com/profiles/xu-zhang219

ScholarMate: https://www.scholarmate.com/P/xu_zhang

Baidu Wikipedia: https://baike.baidu.com/item/张旭/20188377

Introduction

The "inverted" relationship between material strength and toughness is the main bottleneck restricting its engineering application. Gradient nano-grain/twin materials achieve both strength and toughness through the gradient construction of twin boundaries and microstructures. The multi-scale material mechanics research group aims at the research deficiencies in the "constitutive relationship" and "microstructure optimization design" of gradient nano-grain/twin materials, and aims to adopt a "bottom-up" multi-scale model building method. Based on molecular dynamics simulation and discrete dislocation dynamics simulation to reveal the dynamic evolution of the material microstructure, and then establish a strain-graded crystal plastic constitutive theory that integrates the anisotropy, inhomogeneity, and multi-scale characteristics of anti-gradient nanocrystalline/twinned materials Its finite element implementation framework finally reveals the relationship between the material microstructure, deformation mechanism and macromechanical behavior, and on this basis, explores the microstructure control of gradient nanocrystalline/twinned materials to improve their mechanical properties. Relevant research not only helps to enrich the multi-scale description of material constitutive theory, but also provides theoretical reference for microstructure control, performance optimization and engineering service of high-performance gradient nanocrystalline/twinned materials. It has important scientific significance and broadness. Engineering application prospects.

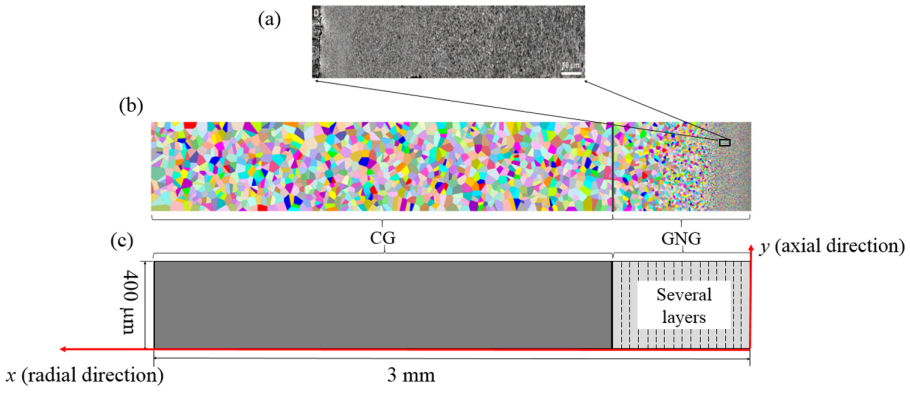

Gradient nanograin model

Fundings

国家自然科学基金面上项目,11872321,激光冲击强化高熵合金循环变形行为的宏微观实验与本构理论研究,2019.01-2022.12。

国家自然科学基金面上项目,11672251,梯度纳米晶粒/孪晶材料的本构建模及微结构设计,2017.01-2020.12

新金属材料国家重点实验室开放基金,2019-Z07,高熵合金的表面纳米化及本构模型研究,2019.07-2021.06。

非线性力学国家重点实验室开放课题,梯度纳米结构IF钢的循环实验及本构建模,2019.04-2020.04。

国防科技重点实验室基金,614220205011802,激光冲击强化对钛合金叶片振动响应特性的影响,2019.01-2020.12。

机械强度与振动国家重点实验开放课题,SV2018-KF-10,钛合金叶片激光冲击强化跨尺度力学行为研究与疲劳寿命预测,2018.01-2019.12。

Related papers

1. X. Lu, X. Zhang*, M. Shi, F. Roters, G. Kang, D. Raabe, Dislocation mechanism based size-dependent crystal plasticity modeling and simulation of gradient nano-grained copper, International Journal of Plasticity. 113 (2019) 52–73.

2. X. Lu, J. Zhao, C. Yu, Z. Li, Q. Kan, G. Kang, X. Zhang*, Cyclic plasticity of an interstitial high-entropy alloy: Experiments, crystal plasticity modeling, and simulations, J. Mech. Phys. Solids (2020), 103971.

3. X. Lu, J. Zhao, Z. Wang, B. Gan, J. Zhao, G. Kang, X. Zhang*, Crystal plasticity finite element analysis of gradient nanostructured TWIP steel, Int. J. Plast. 130 (2020) 102703.

4. J. Zhao, X. Lu, Q. Kan, F. Yuan, S. Qu, G. Kang, X. Zhang*, Multiple mechanism based constitutive modeling of gradient nanograined material, International Journal of Plasticity. 125 (2020/02/01) 314-330.

5. J. Zhao, Q. Kan, L. Zhou, G. Kang, H. Fan*, X. Zhang*, Deformation mechanisms based constitutive modelling and strength-ductility mapping of gradient nano-grained materials, Materials Science and Engineering: A. 742 (2019) 400–408.

6. 熊健, 魏德安, 陆宋江, 阚前华, 康国政,张旭*, 位错密度梯度结构Cu单晶微柱压缩的三维离散位错动力学模拟, 金属学报. 55(2019-04) 1476–1486.

7. X. Zhang, J. Xiong, H. Fan, M. Zaiser*, Microplasticity and yielding in crystals with heterogeneous dislocation distribution, Modelling and Simulation in Materials Science and Engineering. 27 (7) (2019-10) 074003.

8. S. Lu, J. Xiong, D. Wei, Y. Ding, B. Zhang, R. Wu, X. Zhang, Effect of Dislocation Mechanism on Elastoplastic Behavior of Crystals with Heterogeneous Dislocation Distribution, Acta Mechanica Solida Sinica (2020-03). Available online 3 March2020, DOI: 10.1007/s10338-020-00160-5.

The Last Update Time : ..