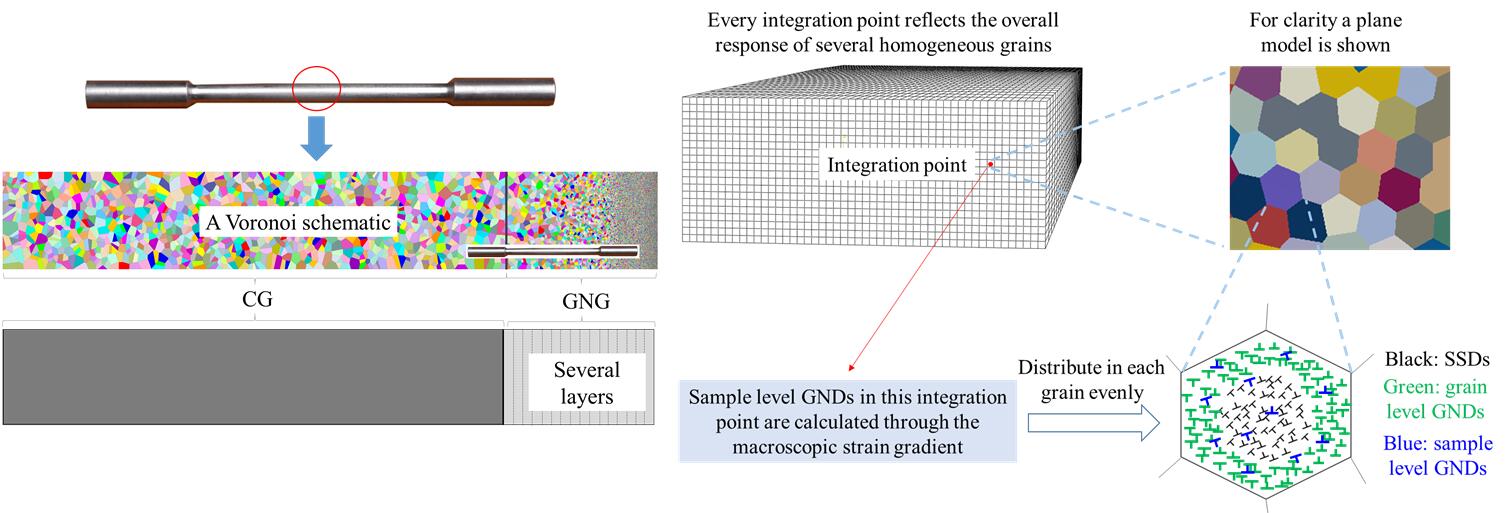

材料强度-韧性的“倒置”关系是制约其工程应用的主要瓶颈。梯度纳米晶粒/孪晶材料通过孪晶界和微结构梯度构筑实现了强韧兼顾。多尺度材料力学课题组针对梯度纳米晶粒/孪晶材料“本构关系”和“微结构优化设计”研究方面的不足,旨在通过“自下而上”的多尺度本构建模方法,基于分子动力学模拟、离散位错动力学模拟揭示材料微结构动态演化,进而建立综合反梯度纳米晶粒/孪晶材料各向异性、非均匀性、多尺度特征的应变梯度晶体塑性本构理论及其有限元实现框架,最终揭示材料微结构、变形机理与宏观力学行为关联,并在此基础上探索梯度纳米晶粒/孪晶材料的微结构调控,以提高其力学性能。相关研究不仅有助于丰富材料本构理论的多尺度描述,还可以为高性能梯度纳米晶粒/孪晶材料的微结构调控、性能优化和工程服役提供理论参考,具有重要的科学意义和广阔的工程应用前景。 国家自然科学基金面上项目,11872321,激光冲击强化高熵合金循环变形行为的宏微观实验与本构理论研究,2019.01-2022.12。 国家自然科学基金面上项目,11672251,梯度纳米晶粒/孪晶材料的本构建模及微结构设计,2017.01-2020.12 新金属材料国家重点实验室开放基金,2019-Z07,高熵合金的表面纳米化及本构模型研究,2019.07-2021.06。 非线性力学国家重点实验室开放课题,梯度纳米结构IF钢的循环实验及本构建模,2019.04-2020.04。 国防科技重点实验室基金,614220205011802,激光冲击强化对钛合金叶片振动响应特性的影响,2019.01-2020.12。 机械强度与振动国家重点实验开放课题,SV2018-KF-10,钛合金叶片激光冲击强化跨尺度力学行为研究与疲劳寿命预测,2018.01-2019.12。 X. Lu, X. Zhang*, M. Shi, F. Roters, G. Kang, D. Raabe, Dislocation mechanism based size-dependent crystal plasticity modeling and simulation of gradient nano-grained copper, International Journal of Plasticity. 113 (2019) 52–73. X. Lu, J. Zhao, C. Yu, Z. Li, Q. Kan, G. Kang, X. Zhang*, Cyclic plasticity of an interstitial high-entropy alloy: Experiments, crystal plasticity modeling, and simulations, J. Mech. Phys. Solids (2020), 103971. X. Lu, J. Zhao, Z. Wang, B. Gan, J. Zhao, G. Kang, X. Zhang*, Crystal plasticity finite element analysis of gradient nanostructured TWIP steel, Int. J. Plast. 130 (2020) 102703. J. Zhao, X. Lu, Q. Kan, F. Yuan, S. Qu, G. Kang, X. Zhang*, Multiple mechanism based constitutive modeling of gradient nanograined material, International Journal of Plasticity. 125 (2020/02/01) 314-330. J. Zhao, Q. Kan, L. Zhou, G. Kang, H. Fan*, X. Zhang*, Deformation mechanisms based constitutive modelling and strength-ductility mapping of gradient nano-grained materials, Materials Science and Engineering: A. 742 (2019) 400–408. 熊健, 魏德安, 陆宋江, 阚前华, 康国政,张旭*, 位错密度梯度结构Cu单晶微柱压缩的三维离散位错动力学模拟, 金属学报. 55(2019-04) 1476–1486. X. Zhang, J. Xiong, H. Fan, M. Zaiser*, Microplasticity and yielding in crystals with heterogeneous dislocation distribution, Modelling and Simulation in Materials Science and Engineering. 27 (7) (2019-10) 074003. S. Lu, J. Xiong, D. Wei, Y. Ding, B. Zhang, R. Wu, X. Zhang, Effect of Dislocation Mechanism on Elastoplastic Behavior of Crystals with Heterogeneous Dislocation Distribution, Acta Mechanica Solida Sinica (2020-03). Available online 3 March2020, DOI: 10.1007/s10338-020-00160-5.方向介绍

基金项目

相关论文

The Last Update Time : ..